Standard magnetic parts often fall short when technical, spatial, or environmental constraints become complex. At MagnetIQ, we offer custom magnetic assemblies engineered to meet specific form factors, material limitations, field requirements or integration demands. Whether for advanced motion systems, harsh environments or regulatory constraints — our tailored assemblies bring performance, simplicity and repeatability to your product architecture.

Custom magnetic Assemblies for Business-Critical Applications

What Are Custom Magnetic Assemblies?

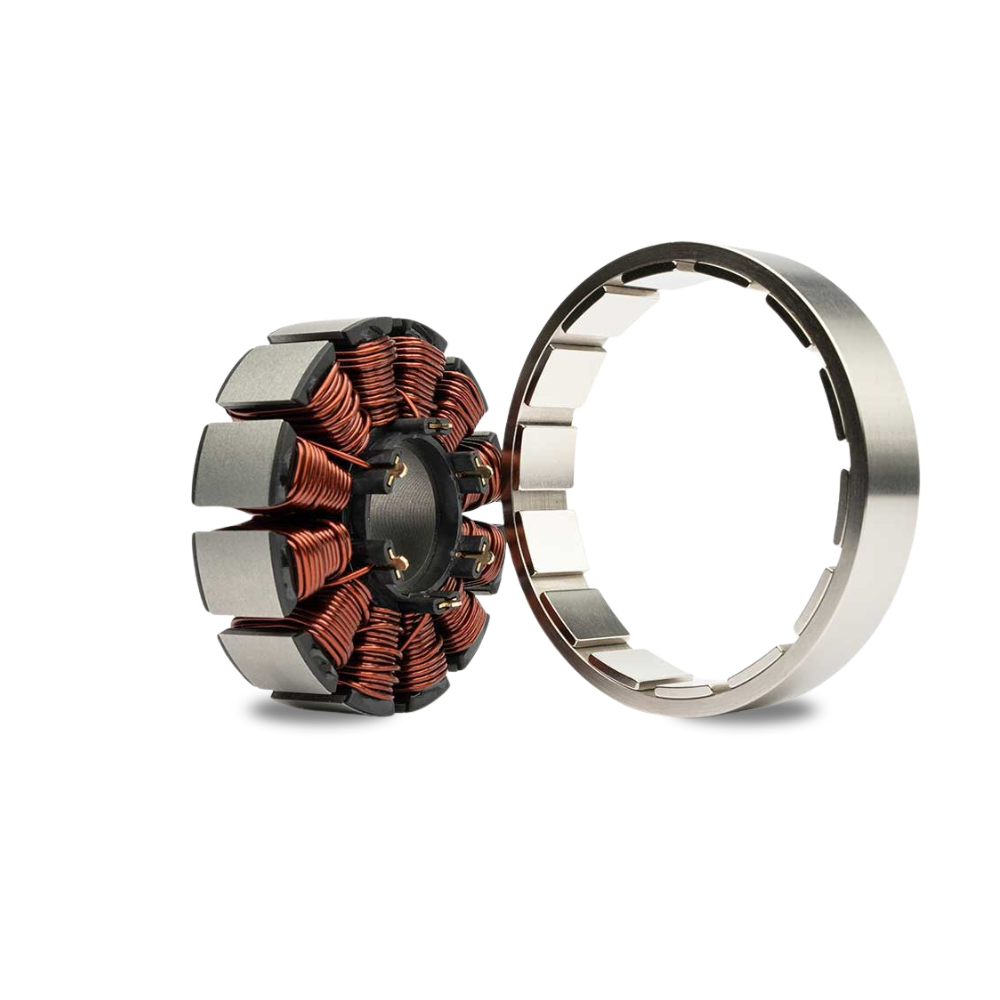

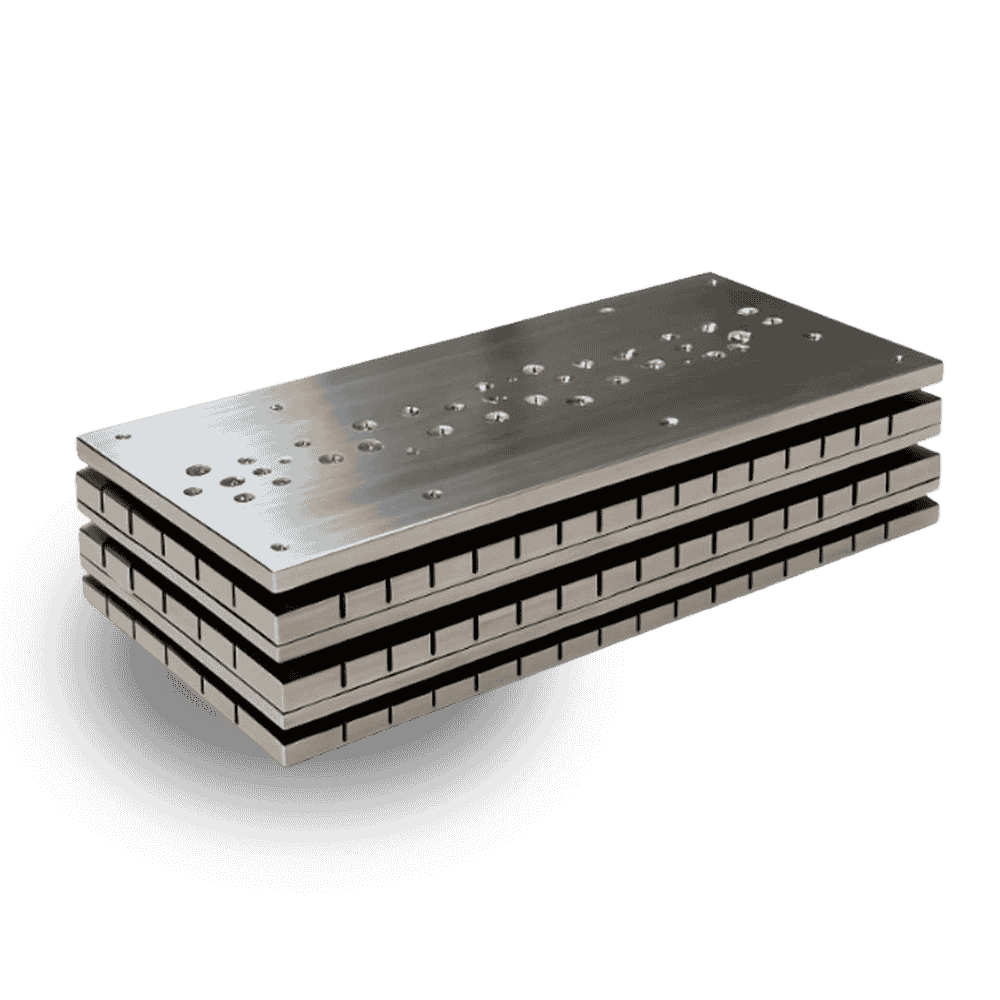

Custom magnetic assemblies are engineered modules that combine permanent magnets with mechanical components, alignment features, and protective elements. Unlike off-the-shelf magnets, these assemblies are purpose-built to fit specific design envelopes and functional needs. A custom magnetic subassembly might include shaped magnets, housings, bonding interfaces, or coatings — all integrated to work as a single, tested unit. They’re often used in applications where alignment, field strength, repeatability, or environmental resistance is critical.

Why Choose a Custom Magnet Instead of Standard?

Standard magnets may offer convenience, but they rarely satisfy the full range of requirements in advanced mechatronic systems. Choosing a custom magnet or assembly allows for optimization in several areas: magnetisation direction, magnetic field profile, thermal performance, corrosion resistance, and integration. This reduces the need for mechanical workarounds, improves product lifetime, and increases performance consistency — especially in safety-critical or space-constrained designs. For businesses, it often leads to faster assembly times and fewer field failures.

Our Approach to Custom Magnet Modules

Off-the-shelf magnets are not designed for your system, so they rarely match the needs of complex systems. Our custom assemblies combine material choice, magnetisation direction, mechanical form, coatings and fixation — all aligned to your technical envelope. We eliminate trial-and-error with a validated solution that fits first time.

How Are Custom Magnets Manufactured for Your Application?

We use a combination of in-house capabilities and trusted partners to manufacture and assemble custom magnetic modules. Production starts with raw magnetic materials — such as NdFeB, SmCo or ferrite — that are shaped and magnetised to spec. Components are then bonded, indexed, aligned, and sometimes encapsulated. All to fit the custom specifics a customer has.

Technical Experience & Production Capabilities of MagnetIQ

- Tooling design based on calculated magnetic assembly forces

- Proven handling and bonding techniques for fragile rare-earths

- Use of cobots and guided manual processes for safe alignment

- Cleanroom-compatible assembly and post-curing capabilities

- Integrated steps: grinding, banding, coating, magnetic measurement

- Proven use in drive and motion, renewable systems, NMR instruments, linear/servo/traction motors, eddy current braking modules, sensors and customer-specific designs

Where Custom Assemblies Add Value

- Miniaturised drives in medical robotics or instruments

- Harsh outdoor or offshore equipment

- Sensitive mechatronics where leakage fields must be limited

- Aerospace assemblies with extreme temperature cycles

- Modular building blocks for high-volume automation

Why choose MagnetIQ?

- Hands-on engineering with magnetic and mechanical integration

- Experience with adhesives, shielding and coatings

- Validated tooling and cobot-assisted assembly lines

- Responsive support in development and scale-up

- Built to spec. Delivered to trust.

Get in touch with our team

Whether you’re looking for a quote, have questions about our services, or want to explore how we can support your needs—just fill out our contact form. We’ll get back to you within 24 hours.