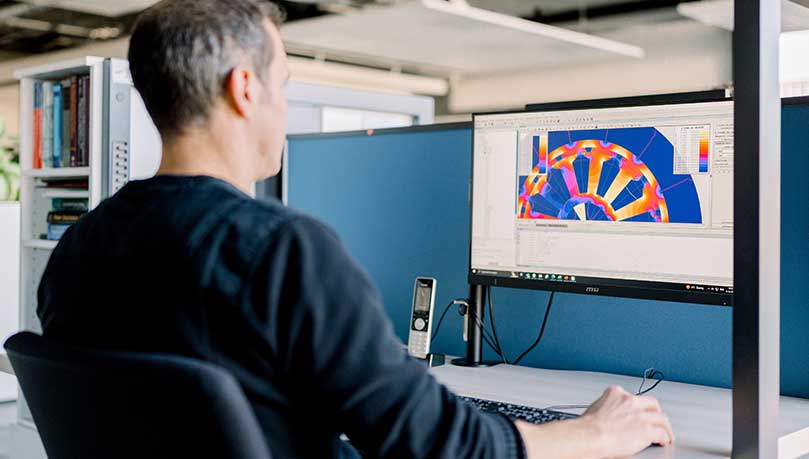

Finite Element Analysis (FEA) is a cornerstone of our engineering workflow. At MagnetIQ, we use magnetic FEA to visualize and calculate flux paths, field strengths, force interactions, and heat distribution in magnet systems — all before a physical prototype is built.

FEA magnetic field Simulations, Force & Field Analysis

What We Simulate

We simulate permanent magnet systems including rotors, stators, magnetic couplings, sensors, brakes, and shielding structures. Typical outputs include flux density maps, force-vs-distance graphs, torque curves, and localized saturation plots. These results enable better design decisions and reduce the need for iterative prototyping.

Tools and Capabilities

We work with professional-grade simulation software and validated material data. Our team is experienced in both 2D and 3D simulations — including static, dynamic, and time-harmonic cases. Simulations are run in close conjunction with physical testing for calibration and accuracy.

Benefits for Clients

Clients benefit from shorter development cycles, reduced cost of errors, and confidence that their magnetic systems will meet the intended specifications. Whether for motor design, sensing applications, or safety-critical components, FEA allows for data-driven design decisions early in the process.

Let’s Simulate It Together

Do you want to explore how simulation can accelerate your magnetic design process? At MagnetIQ, we combine simulation expertise with hands-on experience. Get in touch to discuss your system challenge and we’ll show you what’s possible with magnetic FEA.

Get in touch with our team

Whether you’re looking for a quote, have questions about our services, or want to explore how we can support your needs—just fill out our contact form. We’ll get back to you within 24 hours.